▶ EOS Engineering & Service

▶ JAPANESE

-

Service

- Blade inspection

and defect evaluation - Repair with the latest

technology

and best methods - Improvement of AEP

and reduction

of fatigue load

and noise by VG - Analysis of lightning risk of site,

improvement, and record of blade - Measures against LE (leading edge) erosion

- Gondola for blade repair (Kaeufer) and lifting device by ActSafe

- Tools and equipment related to blade repair

- Blade inspection

- Company

- Contact

Hazards material warehouse

Hazards material warehouse Blade repair material

Blade repair material Gondola

Gondola Sky Box

Sky Box Repair with rope

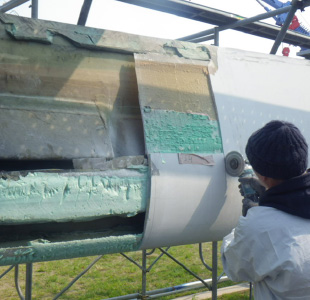

Repair with rope Repair on the ground

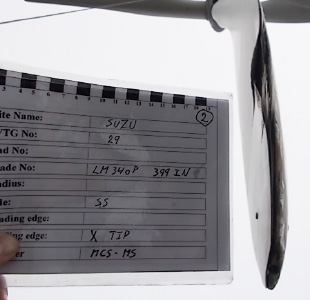

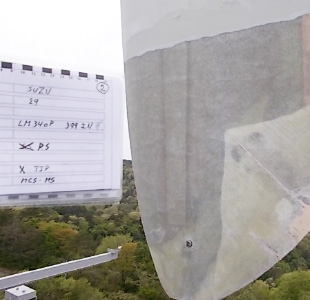

Repair on the ground Tip crack

Tip crack Tip crack repair

Tip crack repair Damage of lightning protection

Damage of lightning protection After repair

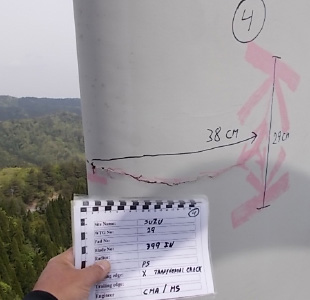

After repair Crack-1

Crack-1 Crack-2

Crack-2 Repair

Repair Repair on the ground

Repair on the ground Repair on the ground

Repair on the ground Erosion-1

Erosion-1 Erosion-2

Erosion-2 Repair of erosion-1

Repair of erosion-1 Repair of erosion-2

Repair of erosion-2 +81-3-3519-3915

+81-3-3519-3915